Next, you will need to allocate the cost of the activities to the individual products. Estimates and allocations based on logical assumptions are better than precise amounts based on faulty assumptions. Costs may be classified as manufacturing costs and non-manufacturing costs. Higher minimum rates might be necessary to limit heterogeneity in rates and reduce transshipment. The unweighted average across deficit countries is 50 percent, and the unweighted average across the entire globe is 20 percent. Weighted by imports, the average across deficit countries is 45 percent, and the average across the entire globe is 41 percent.

- Since nonmanufacturing overhead costs are outside of the manufacturing function, these nonmanufacturing costs are immediately expensed in the accounting period in which they are incurred.

- “Trade elasticities, heterogeneity, and optimal tariffs,” Journal of International Economics, 114, 44-62.

- Examples include wood in furniture, steel in automobile, water in bottled drink, fabric in shirt, etc.

- Mastering the distinction between manufacturing and non-manufacturing costs is vital for effective managerial accounting.

- Hence, they are considered period costs rather than product costs.

Examples

By understanding these cost classifications, you can make informed decisions that enhance financial performance and strategic planning. Some valuable items that cannot be measured and expressed in dollars include the company’s outstanding reputation, its customer base, the value of successful consumer brands, and its management team. As a result these items are not reported among the assets appearing on the balance sheet. Cost of goods sold is usually the largest expense on the income nonmanufacturing costs include statement of a company selling products or goods. Cost of Goods Sold is a general ledger account under the perpetual inventory system.

Direct materials:

Since they are not allocated to goods produced, these costs never appear in the cost of inventory on a firm’s balance sheet. One of the main financial statements (along with the statement Insurance Accounting of comprehensive income, balance sheet, statement of cash flows, and statement of stockholders’ equity). The income statement is also referred to as the profit and loss statement, P&L, statement of income, and the statement of operations. The income statement reports the revenues, gains, expenses, losses, net income and other totals for the period of time shown in the heading of the statement. If a company’s stock is publicly traded, earnings per share must appear on the face of the income statement. Even though nonmanufacturing overhead costs are not product costs according to GAAP, these expenses (along with product costs and profit) must be covered by the selling prices of a company’s products.

Advance Your Accounting and Bookkeeping Career

The balance sheet reports the assets, liabilities, and owner’s (stockholders’) equity at a specific point in time, such as December 31. The balance sheet is also referred to as the Statement of Financial Position. Examples of marketing and selling costs include advertising costs, order taking costs and salaries of sales persons etc.

- Manufacturing costs refer to those that are spent to transform materials into finished goods.

- Manufacturing and non-manufacturing costs together form total costs for a manufacturing entity.

- The unweighted average across deficit countries is 50 percent, and the unweighted average across the entire globe is 20 percent.

- This article looks at meaning of and differences between two main cost categories for a manufacturing entity – manufacturing cost and non-manufacturing cost.

- Instead these expenses are reported on the income statement of the period in which they occur.

- Thus, management attention must be focused on both the core and the ancillary costs to control and manage them with a view to maximize profitability on long term basis.

A manufacturing entity incurs a plethora of costs while running its business. While manufacturing or production costs are the core costs for a manufacturing entity, the other costs are also just as important as they too affect overall profitability. Thus, management attention must be focused on both the core and the ancillary costs to control and manage them with a view to maximize profitability on long term basis. Selling Expenses – also called Selling and Distribution Expenses. Examples include advertising costs, salaries and commission of sales personnel, storage costs, shipping and delivery, and customer service.

Case Study: Cost Management in a Canadian Manufacturing Firm

- The sum of direct labor cost and manufacturing overhead cost is known as conversion cost.

- Nonmanufacturing overhead costs are the business expenses that are outside of a company’s manufacturing operations.

- To help clarify which costs are included in these three categories, let’s look at a furniture company that specializes in building custom wood tables called Custom Furniture Company.

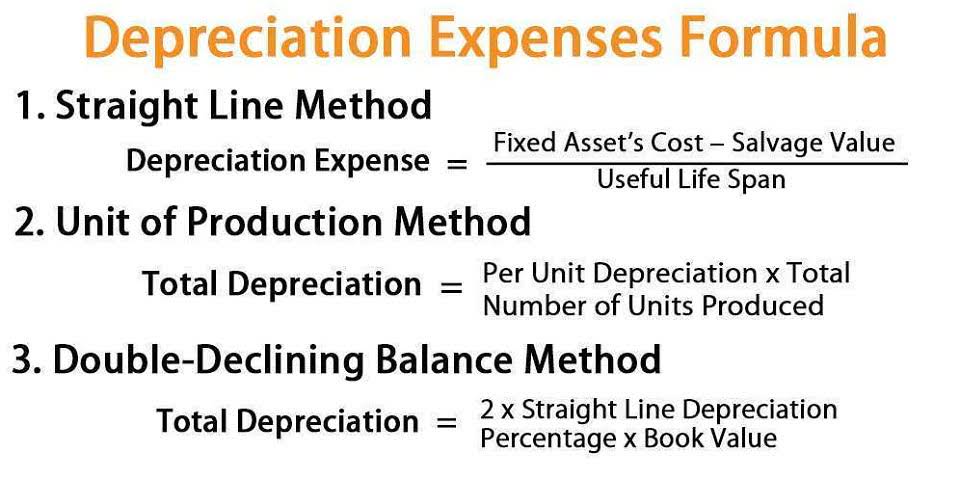

- Manufacturing overhead might include the cost of factory utilities, depreciation on manufacturing equipment, and the salaries of factory supervisors.

- Costs that are not related to the production of goods are called nonmanufacturing costs23; they are also referred to as period costs.

Cost of sales represented the highest cost on the income statement at $26,600,000,000. The second highest cost on the income statement—selling and general and administrative expenses—totaled $22,800,000,000. These expenses are period costs, meaning they must be expensed in the period in which they are incurred. On the other hand, a product with a low gross profit may actually be very cash flow profitable, if it uses only a minimal amount of administrative and selling expense. All these costs – marketing and sales expenses, G&A, and R&D – are non-manufacturing overhead costs. These costs aren’t directly related to the physical production of their devices but are essential to running the business and its long-term growth.

What are non-manufacturing costs or period costs?

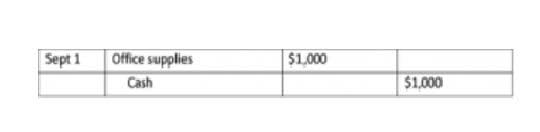

For accounting purposes, nonmanufacturing costs are expensed periodically (typically in the period they are incurred). However, for management objectives, managers frequently require the assignment of nonmanufacturing costs to goods. This is especially true for specific product-related commissions and promotions.